Clarity

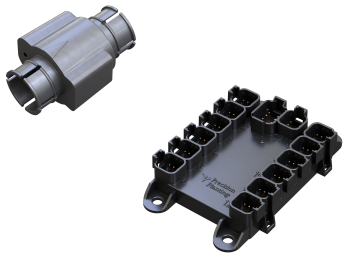

Standard blockage systems tell if a product is flowing, but that’s about it. Clarity from Precision Planting gives you a high-definition look into air seeders, box drills, dry fertilizer applicators and strip-till bars in real-time. The Clarity system displays and maps flow variability and product blockage metrics, row-by-row, on the 20|20 monitor in your cab.